A gearbox inspection is a crucial step in ensuring that a gearbox operates efficiently and reliably throughout its service life. Regular inspections help detect issues before they escalate into costly repairs or unexpected failures, reducing downtime and enhancing the performance of machinery and vehicles. Gearbox inspections are typically performed by experienced technicians who assess the internal and external components to identify signs of wear, damage, or malfunction.

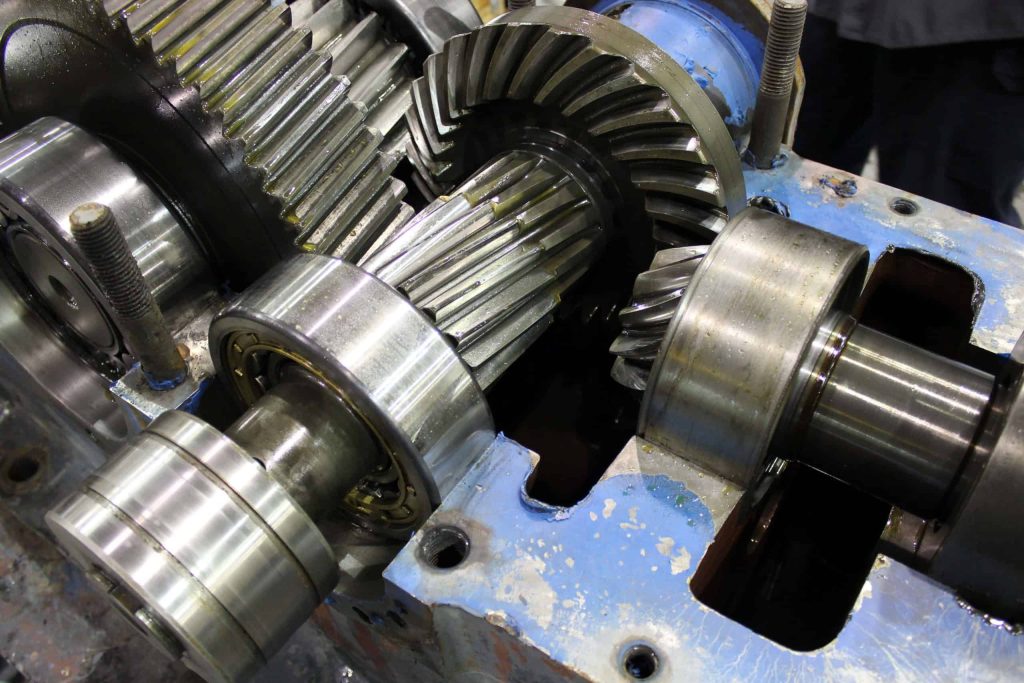

Gear teeth inspection

Inspecting the condition of the gears is one of the most important steps in a gearbox inspection. Gear teeth wear, cracks, or chips can significantly affect the performance of the gearbox.

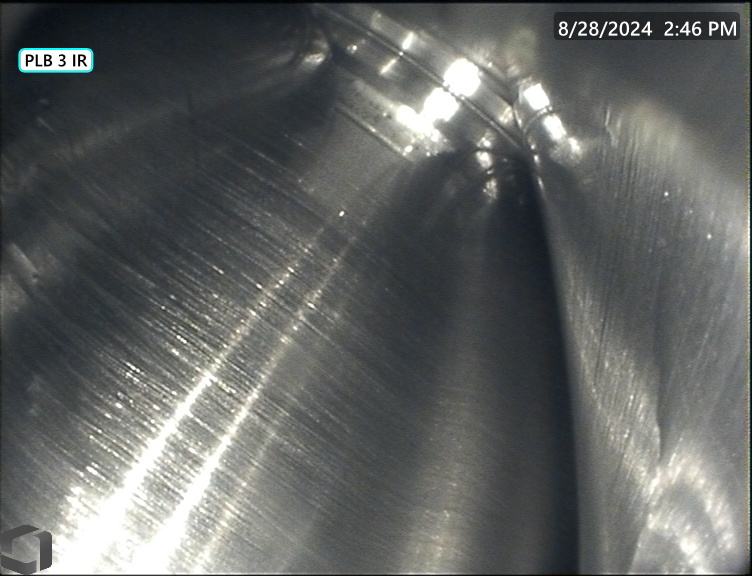

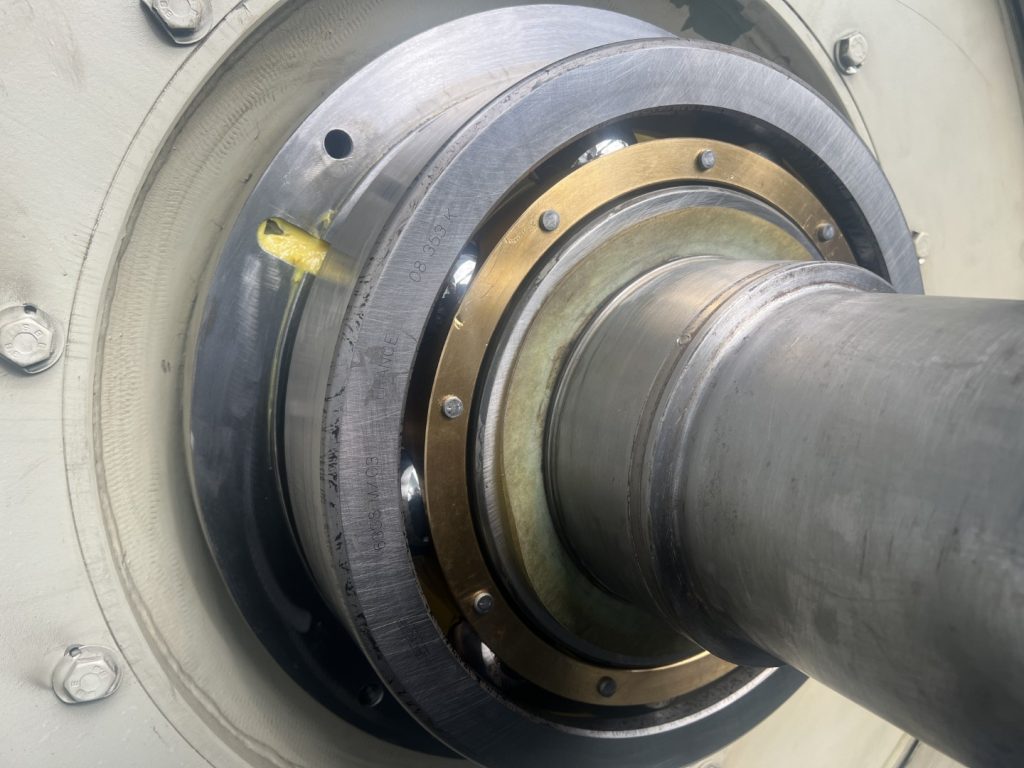

Bearing inspection

Bearings and shafts support the rotating gears within the gearbox and are subject to high loads and stress.

Check for Backlash: Backlash is the small movement or play between gears. Excessive backlash can indicate worn gears, shafts, or bearings, leading to inefficient operation and noise.