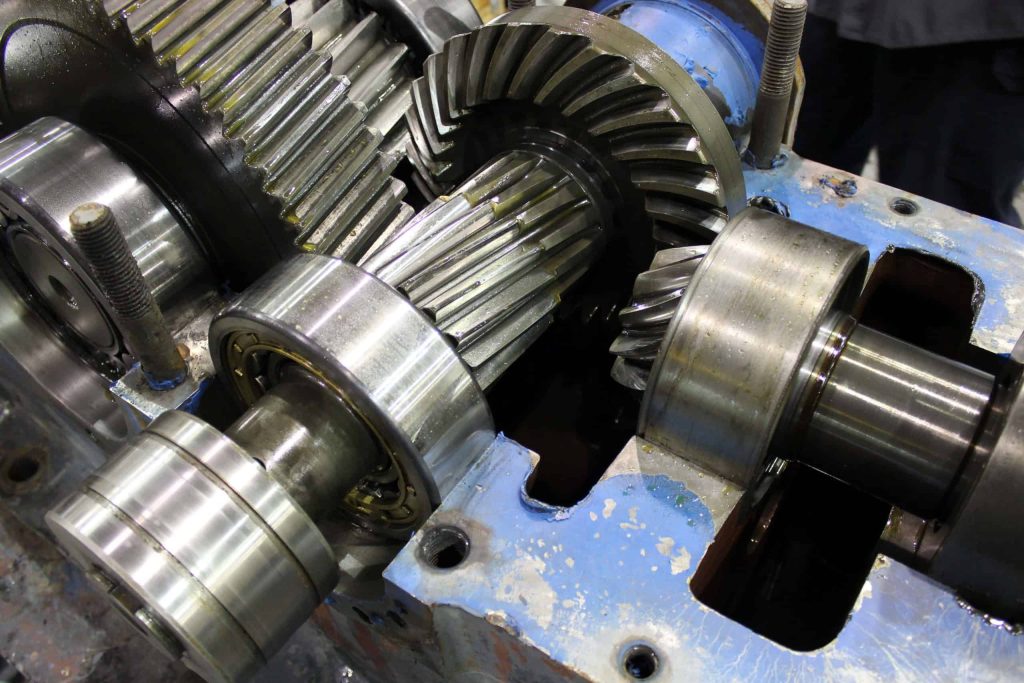

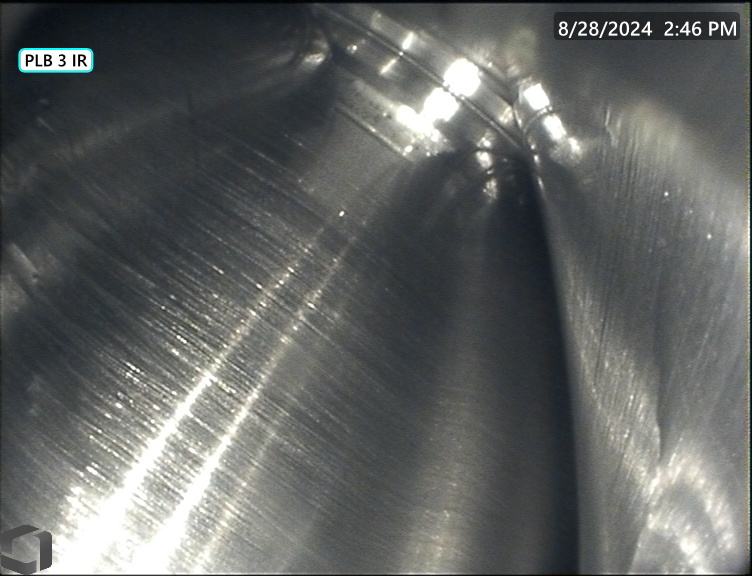

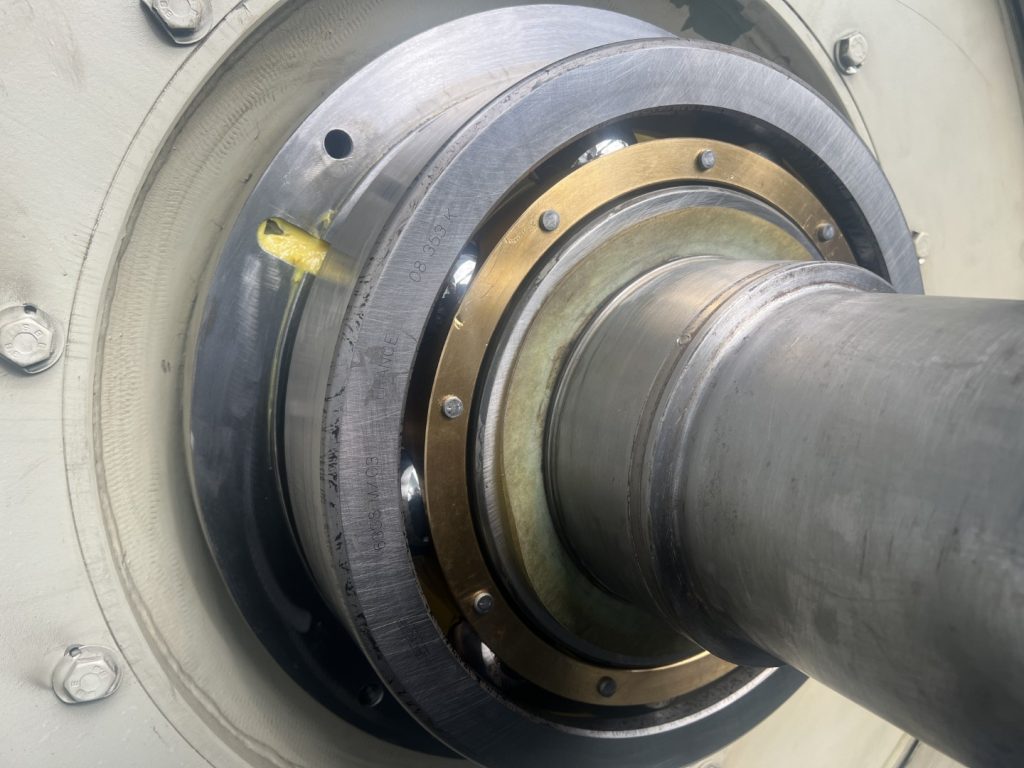

Proper gearbox alignment is critical for ensuring the efficiency, longevity, and reliability of the gearbox and the machinery it powers. Misalignment can lead to excessive wear, increased friction, overheating, and eventually, premature failure of the gearbox components. Whether you’re dealing with industrial machinery, automotive systems, or large-scale equipment, ensuring that the gearbox is aligned correctly is one of the most important aspects of maintenance and operation.

Importance of Gearbox Alignment

Importance of Gearbox Alignment

Extended Gearbox Lifespan: Proper alignment minimizes the chance of excessive loading or wear on critical components, which helps to extend the lifespan of the gearbox and associated machinery.