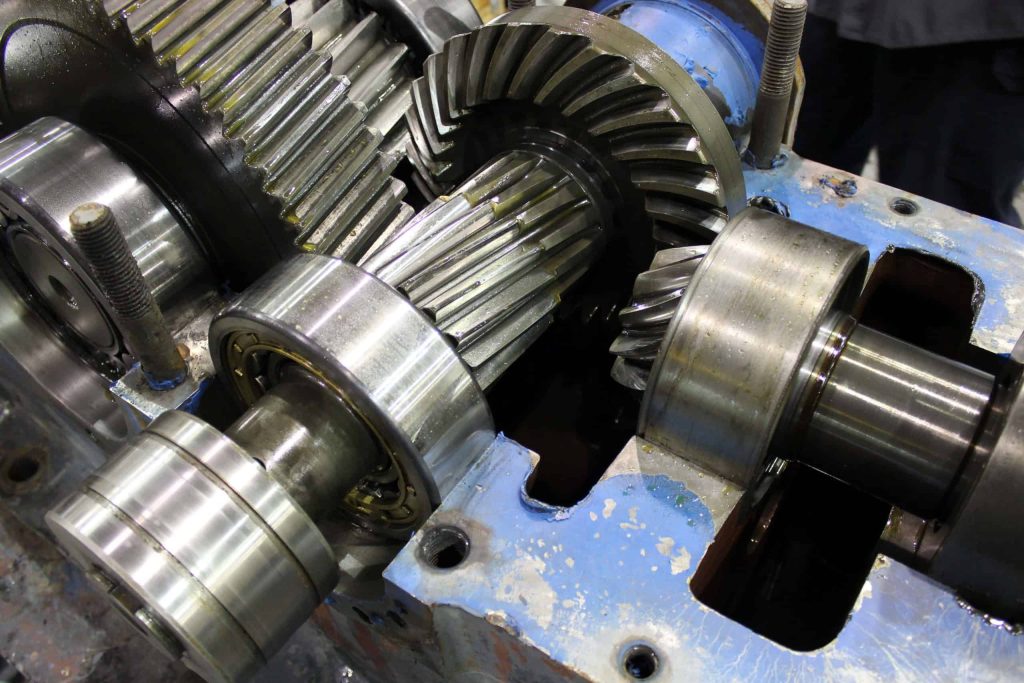

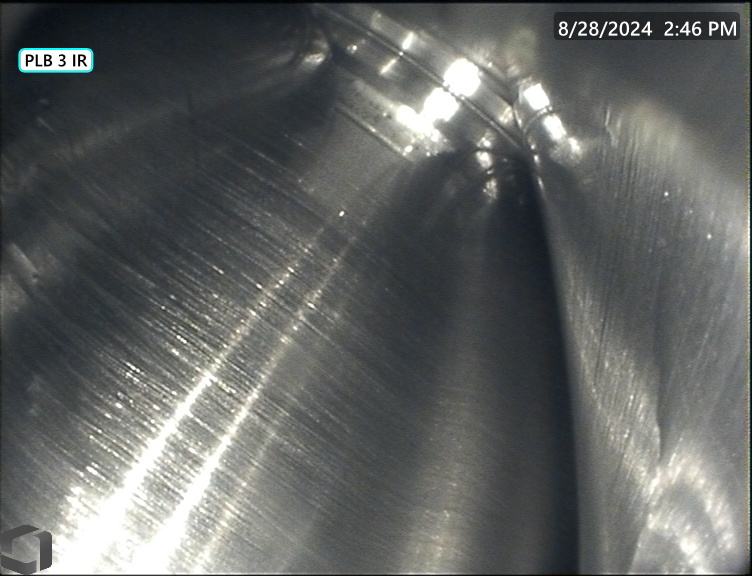

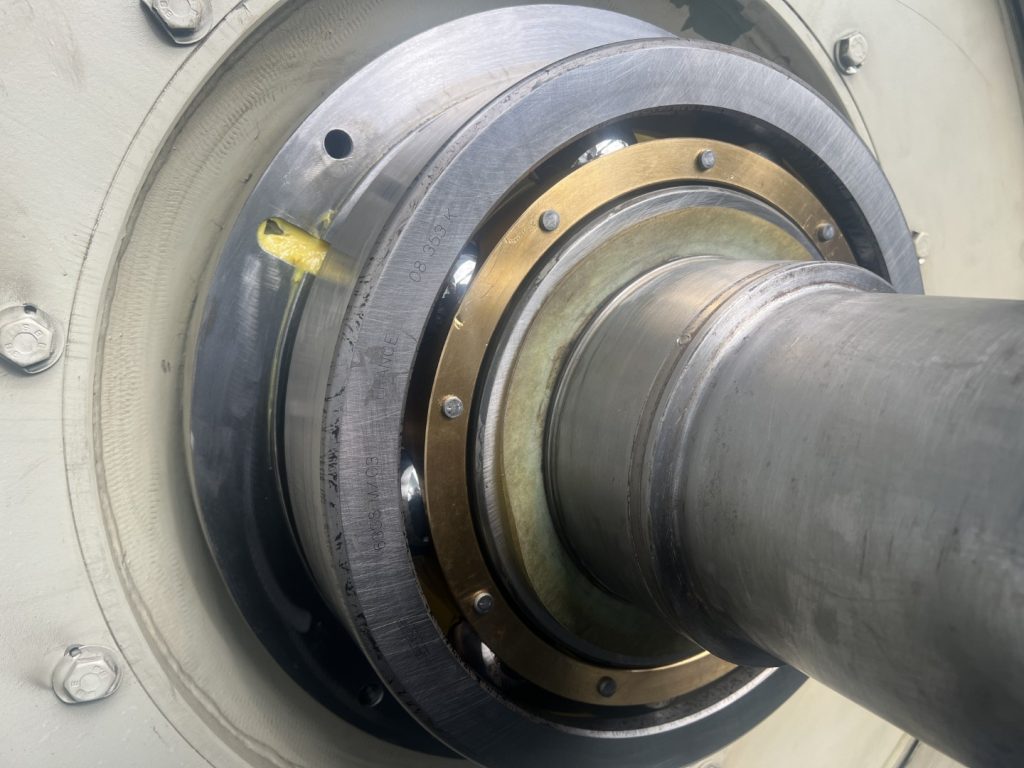

Repairing a gearbox typically involves several key steps to diagnose, disassemble, inspect, replace, and reassemble the unit to restore its functionality.

Gearbox repairs are an essential part of maintaining the efficiency and longevity of mechanical systems. Whether you are dealing with industrial machinery, vehicles, or heavy equipment, regular maintenance and timely repairs can save significant costs, reduce downtime, and improve operational performance. When faced with gearbox issues, it’s critical to engage with qualified repair technicians who can assess the damage, recommend appropriate solutions, and restore your gearbox to peak performance.